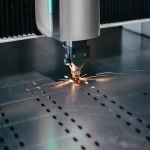

In the tool manufacturing industry, clear identification and durable branding are essential for quality assurance and product traceability. Laser marking provides a precise, fast, and permanent solution for engraving serial numbers, logos, part numbers, and safety information directly onto tools.

Key Advantages of Laser Marking in Tool Manufacturing:

-

High Precision: Mark intricate designs or small text accurately on metal and alloy tools.

-

Durable & Permanent: Marks withstand wear, corrosion, and harsh industrial environments.

-

Non-Contact Process: Reduces the risk of damaging delicate or finely machined tools.

-

Branding & Customization: Easily engrave company logos or product codes for authenticity.

-

Efficiency: Speeds up production compared to traditional stamping or engraving methods.

-

Traceability: Helps in inventory management, warranty tracking, and anti-counterfeiting.

By integrating laser marking technology, tool manufacturers can ensure product reliability, enhance brand visibility, and maintain high standards of quality control in every production batch.