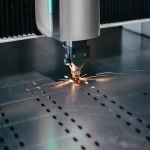

Laser marking machines are a critical investment for industries requiring precision and high-quality marking. Proper maintenance and safety practices ensure longevity, consistent performance, and operator safety. Neglecting these can lead to machine downtime, reduced efficiency, or even accidents.

Maintenance Tips:

-

Regular Cleaning: Keep lenses, mirrors, and work surfaces clean to maintain marking quality.

-

Check Cooling Systems: Ensure proper functioning of water or air cooling systems to prevent overheating.

-

Lubrication: Apply lubrication to moving parts as recommended in the user manual.

-

Software Updates: Keep the machine software updated for optimal performance and new features.

-

Routine Inspections: Regularly inspect electrical connections, cables, and mechanical components for wear or damage.

Safety Tips:

-

Wear Protective Gear: Use laser safety goggles and appropriate clothing.

-

Proper Ventilation: Ensure adequate ventilation to remove fumes or particles generated during marking.

-

Follow Manufacturer Guidelines: Always operate the machine according to the user manual.

-

Avoid Direct Exposure: Never look directly at the laser beam or allow skin exposure.

-

Emergency Protocols: Keep fire extinguishers and first-aid kits nearby, and train operators on emergency procedures.

By following these maintenance and safety tips, businesses can extend the life of their laser marking machines, maintain high-quality output, and ensure a safe working environment for operators.