The bag manufacturing industry is going through a revolution of sorts. From everyday totes to premium leather bags, precision and durability are now non-negotiable.

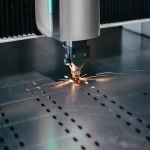

That’s why, today, whether it’s a large-scale manufacturer or a small start-up brand, most are turning to laser technology instead of traditional methods. In this article, we’ll discuss the magic of CO2 Laser for fabric technology and explore why it has become the MVP of modern bag manufacturing.

Here are some of the benefits the CO2 laser for fabric technology offers and simplifies the production:

- Creates perfectly sealed edges: The laser’s heat melts and fuses the fabric’s edges, cutting them to create perfectly sealed edges, ensuring a cleaner and more durable finish.

- Prevents Fabric Distortion: Being contactless, the system eliminates pressure, pulling, and stress that could distort delicate fabrics or costly leather.

- Digital design integration: Any changes in the design, custom orders, or even shorter production runs can be handled effortlessly, as you can modify a digital design file in no time and seamlessly continue the operation.

- Reduced wastage: This modern technology arranges pattern pieces on the fabric roll in a compact layout, minimizing the space between cuts and reducing wastage.

- Faster mass production: Thanks to automation, the precision and efficiency in fabric marking and cutting ensure a continuous production cycle with minimal operator involvement.