How laser cutting works: The process step-by-step

The automated process of laser cutting is highly precise and repeatable. Here is a breakdown of how it works:

- Design creation. A 2D or 3D design is created using computer-aided design (CAD) software. The design is then converted into a G-code file, which the laser cutter can interpret as instructions for the cutting path.

- Beam generation. The machine's laser source, or resonator, generates a highly concentrated beam of light. Depending on the type of laser, this is done using a gas mixture, a doped crystal, or optical fibers.

- Beam delivery and focus. A system of mirrors and lenses guides and focuses the laser beam into a pinpoint spot on the material's surface. The focal point is crucial, as it is where the beam's energy is most concentrated.

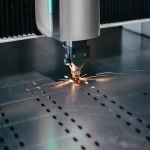

- Material interaction. The focused laser beam makes contact with the material, heating it to its melting, burning, or vaporization point. The rapid thermal separation process creates the cut.

- Gas assistance. An assist gas, such as nitrogen or oxygen, is directed through a nozzle to the cutting point to blow away molten material and debris. The choice of gas can affect the cut's quality and speed.

- Motion control. A motion control system, also directed by the G-code, moves the laser head or the material bed along the programmed path to create the desired shape or design.

From heavy industrial applications to delicate artistic creations, laser cutting continues to push the boundaries of what is possible in design and manufacturing.